Are there any specific maintenance requirements for these Plastic Injection Steel Hooks 17mm Flat Bungee Cords?

1. Inspection and Cleaning:

Regularly inspect the bungee cords for any signs of wear, fraying, or damage. This visual check should include a close examination of the plastic injection steel hooks. Clean the cords with a mild soap solution to remove dirt and debris, especially if they have been exposed to challenging environments.

Example: If left uncleaned, accumulated dirt can weaken the material and compromise the overall strength of the cords, leading to potential failure during use.

2. Storage:

Proper storage is key to preventing unnecessary wear and maintaining elasticity. Store the

17mm Flat Bungee Cords with Plastic Injection Steel Hooks in a cool, dry place away from direct sunlight. Avoid exposing them to extreme temperatures, as this can impact the rubber and overall material integrity.

Example: Long-term exposure to sunlight can cause the rubber to deteriorate, reducing the bungee cords' effectiveness over time.

3. Avoid Overloading:

While these 17mm flat bungee cords are designed for durability, it's essential to adhere to their weight capacity. Overloading can lead to stretching beyond the cords' intended limits, causing permanent damage.

Example: Exceeding the weight limit may result in the steel hooks breaking or the rubber losing its elasticity, rendering the bungee cords unsafe for further use.

4. Replace Damaged Parts:

If any part of the bungee cords, including the plastic injection steel hooks, shows signs of damage, it is crucial to replace them promptly. Delaying replacement can compromise the overall safety and effectiveness of the cords.

Example: A damaged steel hook may fail to secure items properly, leading to potential accidents or damage during transport.

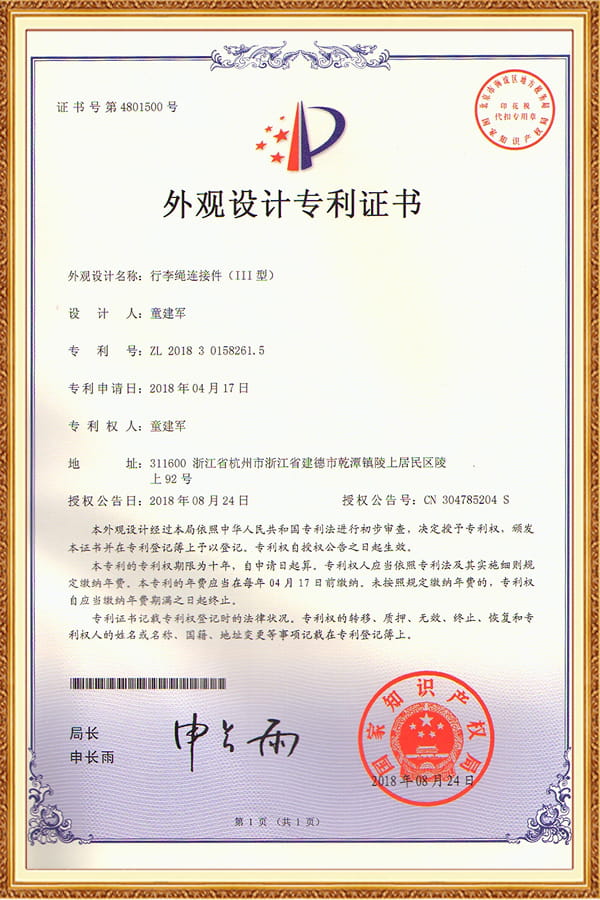

We are

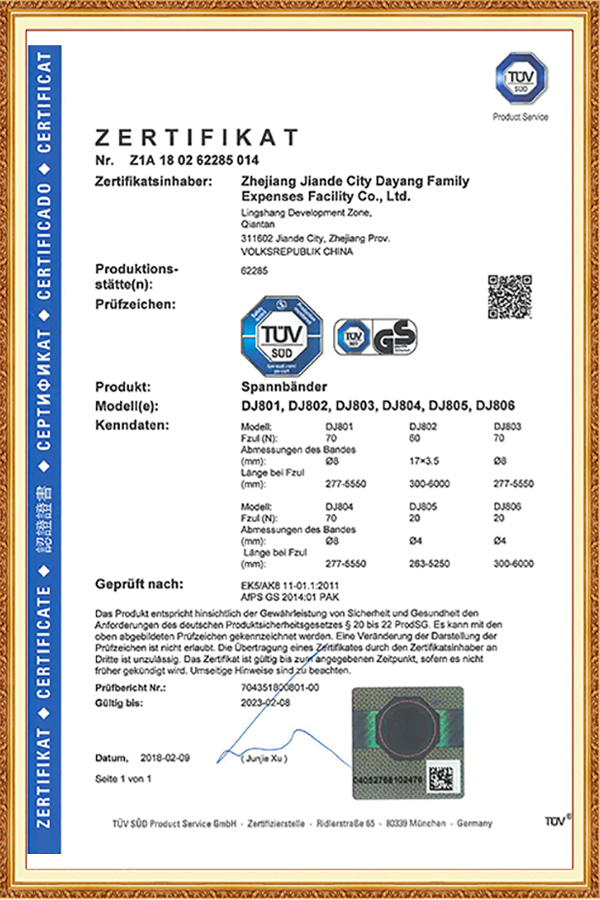

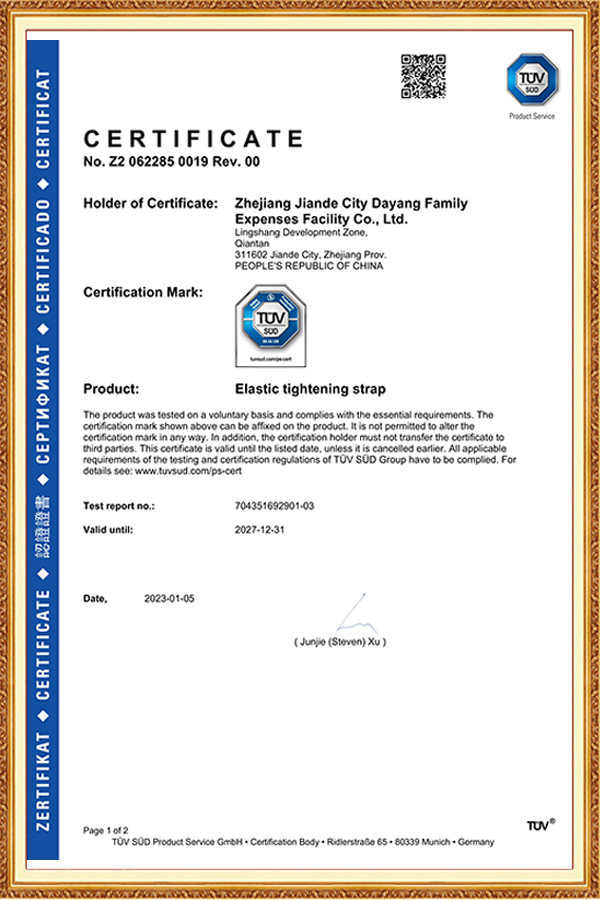

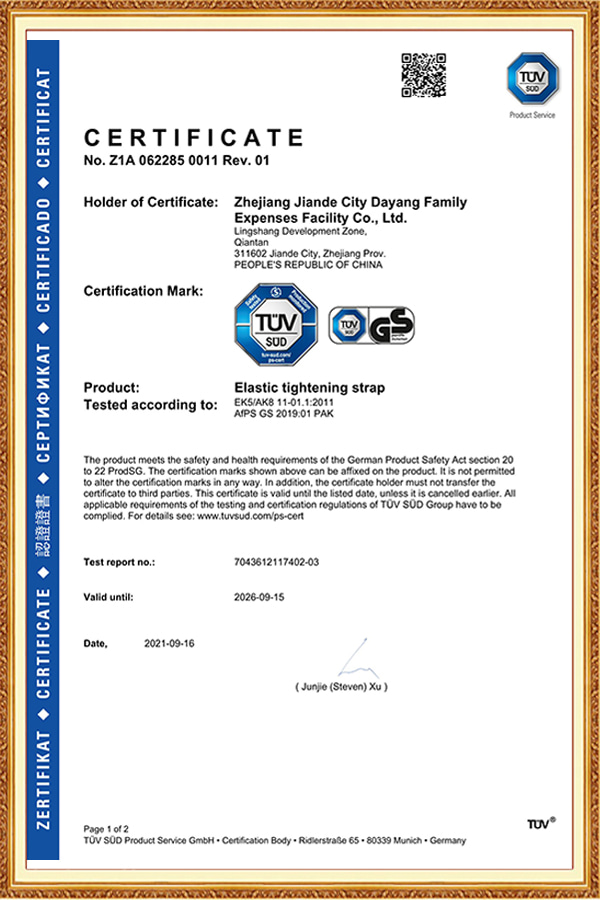

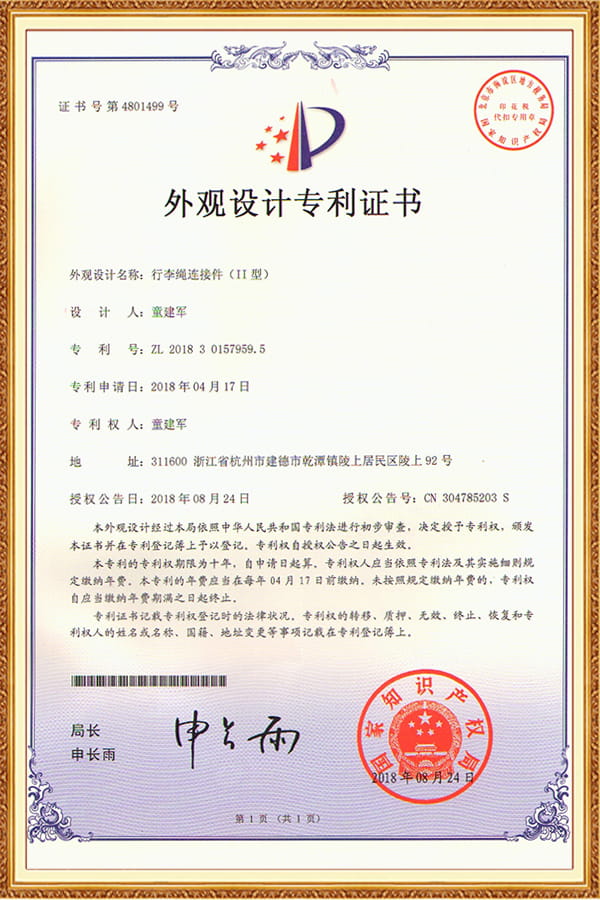

OEM/ODM Plastic Injection Steel Hooks 17mm Flat Bungee Cords Factory, With new design, delicate appearance, high quality, our products have been exported to various countries.

get a free quote

get a free quote

get a free quote

get a free quote

EN

EN  Español

Español