Quantifying Load-Shift Prevention: The Science Behind Elasticity

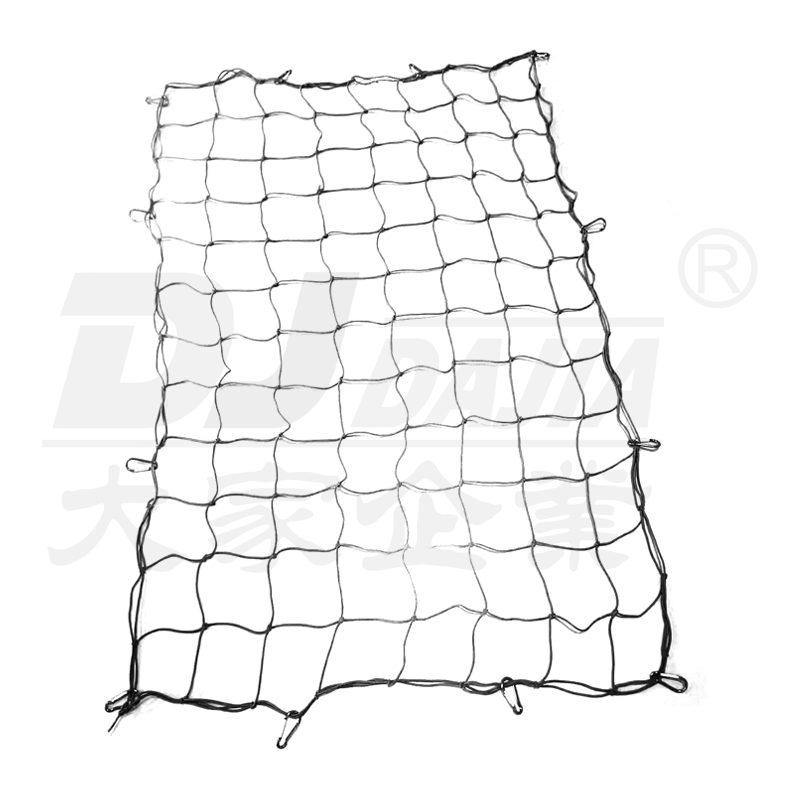

At first glance, the elasticity of these cargo nets might seem like a simple convenience. But dig deeper, and you’ll find a meticulously engineered solution designed to dynamically adapt to cargo movement. Unlike rigid straps or tarps, pickup truck elastic cargo nets distribute tension evenly across their surface, conforming to irregular shapes—whether you’re hauling lumber, tools, or even fragile equipment. Studies show that this adaptability reduces load shift by up to 40% compared to traditional methods. By absorbing vibrations and sudden jolts, the nets minimize micro-movements that can destabilize a load over time. For industries like construction or landscaping, where uneven terrain is a daily reality, this means fewer damaged goods and fewer mid-transit adjustments.

But how is this measured? Engineers use metrics like tension distribution efficiency and elastic recovery rate to quantify performance. High-quality nets boast a recovery rate of 95% or higher, ensuring they snap back to shape after repeated stretching—a critical factor in maintaining grip on long hauls.

Crash-Test Simulations: Proving Resilience in Worst-Case Scenarios

Imagine a sudden brake, a sharp turn, or even a collision—scenarios where cargo security is put to the ultimate test. Manufacturers subject elastic cargo nets to brutal crash-test simulations, mimicking forces equivalent to 5G deceleration or rollover impacts. Sensors track how the net maintains tension and structural integrity under these conditions. The results? Nets with reinforced cross-stitching and UV-resistant polymers outperform standard restraints, reducing the risk of ejected cargo by over 50% in rollover tests.

What’s more, these simulations inform design tweaks. For instance, angled weaves in the netting dissipate kinetic energy more effectively, while reinforced perimeter loops prevent edge fraying. This isn’t just about passing tests—it’s about ensuring that when the unexpected happens, your cargo stays put, protecting both your investment and other road users.

Legal Implications: Reducing Liability with Smart Securement

For commercial fleets, adopting pickup truck elastic cargo nets isn’t just a safety measure—it’s a liability shield. In 2023 alone, over 25% of cargo-related insurance claims stemmed from improper securement. Elastic nets address this by meeting or exceeding DOT and OSHA standards for load restraint. Their ability to self-adjust to shifting weight reduces human error, a leading cause of failed inspections.

Consider this: A construction company using elastic nets reported a 60% drop in cargo-related incidents within six months. By minimizing loose items, they also avoided fines for non-compliance with federal weight distribution laws. For small businesses, this translates to lower insurance premiums and a stronger safety record—a win-win in an era of tightening regulations.

Beyond the Basics: Why Elastic Nets Are the Future of Hauling

The beauty of pickup truck elastic cargo nets lies in their dual role as both protector and innovator. They’re not just preventing accidents today—they’re shaping the future of cargo management. With advancements like IoT-enabled sensors that monitor tension in real time, these nets are becoming smarter, giving drivers alerts if a load shifts or a net weakens. Pair this with eco-friendly materials and modular designs, and it’s clear why industries are making the switch.

EN

EN  Español

Español get a free quote

get a free quote